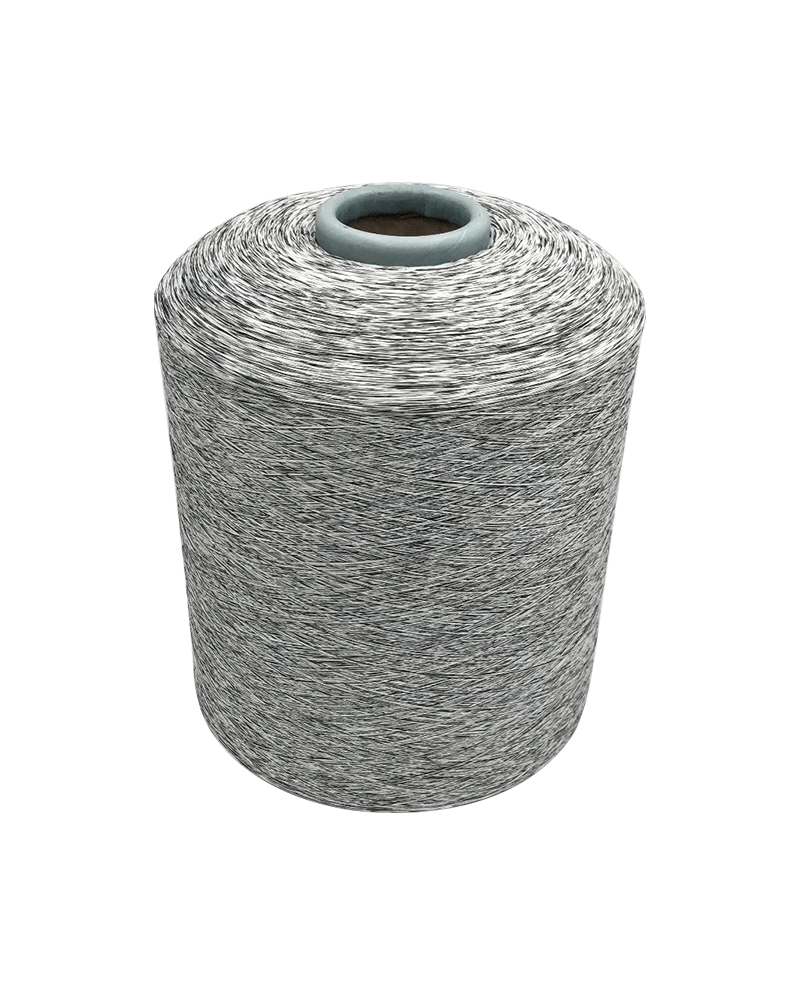

Does CD Yarn Pill?

CD yarn, also known as compact yarn, is a type of yarn that is produced using a compact spinning technique. This spinning method produces a smooth, denser yarn that is less prone to pilling than conventional ring-spun yarn.

Pilling is the formation of small, tangled balls of fiber on the surface of a fabric, and it occurs when loose fibers rub against each other and become entangled. Because compact yarn has fewer loose fibers than conventional ring-spun yarn, it is less likely to pill.

That being said, even compact yarn can pill if it is made from fibers that have a tendency to pill, such as wool or acrylic. In addition, factors such as fabric construction, abrasion, and laundering can also contribute to pilling, regardless of the type of yarn used.

In summary, while CD yarn is less prone to pilling than conventional ring-spun yarn, its tendency to pill will depend on the type of fiber used and other factors related to fabric construction and care.

Solutions To Common Problems Of CD Yarn

CD yarn, also known as compact yarn, is a type of yarn that is produced using a compact spinning technique. While this spinning method produces a smoother, denser yarn that is less prone to pilling than conventional ring-spun yarn, it can still be susceptible to some common problems. Here are some solutions to these problems:

Uneven twist: Uneven twist can result in yarn that is weaker in some areas than others, which can lead to breakdown during weaving or knitting. To prevent uneven twist, it is important to maintain consistent tension throughout the spinning process and to monitor the twist level regularly.

Fiber entanglement: Compact yarn can sometimes experience fiber entanglement, which can cause the yarn to break or become uneven. To prevent fiber entanglement, it is important to use well-prepared fibers and to maintain consistent tension during the spinning process.

Bobbin defects: Defects such as broken ends or uneven winding can occur during the winding process, which can affect the quality of the finished yarn. To prevent bobbin defects, it is important to monitor the winding process closely and to make sure that the winding tension is consistent.

Yarn slippage: Compact yarn can be more prone to slippage than conventional ring-spun yarn, especially if it is used in high-tension applications such as weaving. To prevent yarn slippage, it may be necessary to use a stronger yarn or to adjust the tension of the loom or knitting machine.

Yarn breakdown: Compact yarn can be more prone to breakdown than conventional ring-spun yarn, especially if it is used in high-tension applications. To prevent yarn breakdown, it is important to use well-prepared fibers, to maintain consistent tension throughout the spinning process, and to monitor the twist level regularly.

Overall, the solutions to common problems of

CD yarn involve careful monitoring and control of the spinning process, as well as attention to the quality of the fibers used and the tension of the loom or knitting machine.

English

English 中文简体

中文简体