Understanding Normal DTY Yarn: A Cornerstone of Modern Textiles

In the complex world of textile manufacturing, few materials are as indispensable—and as quietly transformative—as Normal Draw Textured Yarn (DTY). This unassuming fiber serves as the backbone of countless everyday fabrics, yet its capabilities extend far beyond the ordinary. Combining durability, flexibility, and aesthetic finesse, Normal DTY Yarn is the silent enabler of modern comfort and performance.

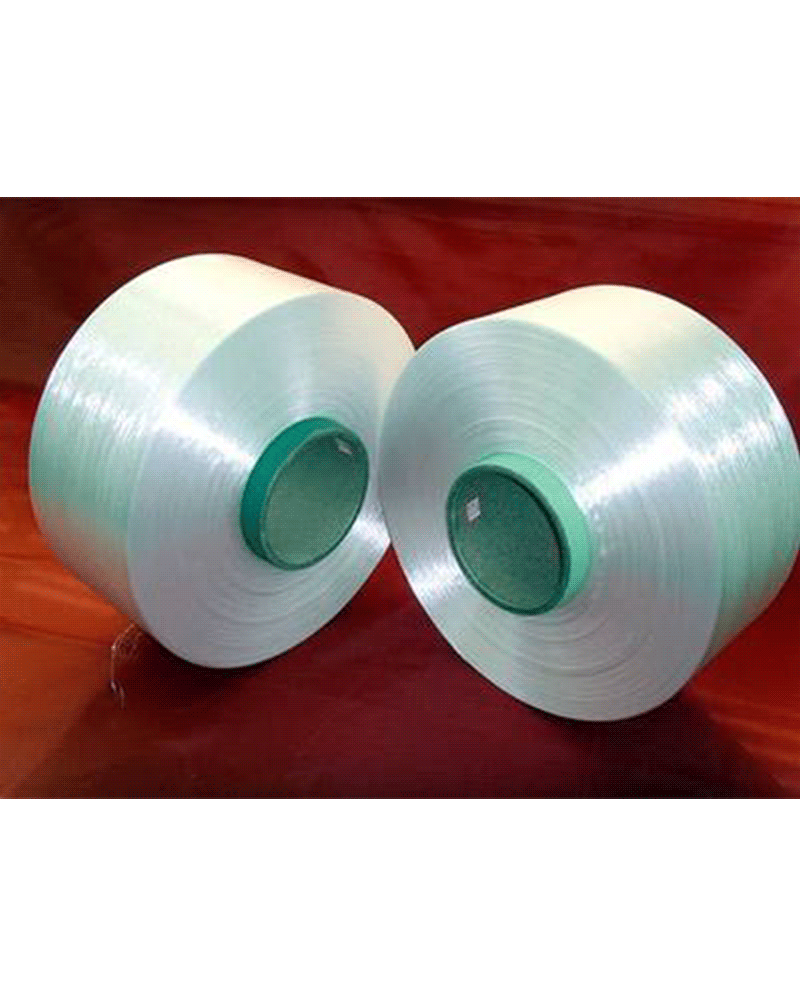

At its core, Normal DTY Yarn is a polyester-based synthetic yarn that undergoes a specialized process known as draw texturing. This mechanical operation imparts both strength and elasticity, converting flat, lifeless filaments into resilient threads with crimped textures and springy behavior. The result? A versatile yarn capable of delivering not just structural integrity but also tactile appeal.

Manufacturers favor Normal DTY Yarn for its dimensional stability, color fastness, and resistance to wrinkles and shrinkage—properties that are not simply desirable, but essential in high-demand consumer goods. From activewear to automotive upholstery, its applications span a multitude of industries, underlining its universal adaptability.

The yarn is available in a variety of deniers and filament counts, each suited to specific requirements. Lower deniers yield soft, lightweight fabrics ideal for intimate wear, while higher deniers provide bulk and durability for industrial textiles. Whether air-interlaced or non-interlaced, semi-dull or full-dull, Normal DTY Yarn can be fine-tuned to meet precise visual and functional standards.

A key advantage lies in its cost-effectiveness without compromising quality. As economies shift and sustainability becomes more than a buzzword, DTY continues to evolve. Recycled versions of DTY Yarn are now gaining traction, helping brands align with environmental mandates without sacrificing product performance.

From a production standpoint, the benefits of working with Normal DTY Yarn extend into efficiency. Its uniform texture ensures smoother weaving and knitting, reducing machine downtime and defects. This efficiency is more than a convenience—it's a competitive edge in a market driven by speed and consistency.

Furthermore, the aesthetic potential of DTY Yarn should not be underestimated. Its textured finish allows for nuanced visual effects, subtle sheen, or complete matte looks depending on post-processing treatments. It is this level of customization that enables designers to innovate freely while maintaining fabric integrity.

In a world increasingly defined by performance textiles, Normal DTY Yarn stands not merely as a raw material but as a catalyst for innovation. It bridges the gap between functional utility and design versatility, proving itself indispensable across product categories.

Professionals in the textile sector understand that not all yarns are created equal. Normal DTY Yarn, with its superior adaptability, performance, and cost efficiency, represents a strategic choice—a material investment that delivers long-term returns in quality, reliability, and market appeal. For manufacturers and designers alike, it’s not just yarn. It’s a foundation.

English

English 中文简体

中文简体