The Unsung Hero of Softness: Demystifying DTY Yarn

In the vast and intricate world of textiles, countless yarn types form the foundation of the fabrics we wear and use daily. Among these, Draw Textured Yarn (DTY) stands out as a workhorse, prized for its unique combination of softness, bulk, and versatility. If you’re involved in manufacturing, sourcing textiles, or simply curious about what makes your favorite fleece so cozy, understanding DTY yarn is essential. This article delves into what DTY is, how it’s made, its key properties, and why it’s such a popular choice across numerous applications.

What Exactly is DTY Yarn?

At its core, DTY stands for Draw Textured Yarn. It’s a type of synthetic filament yarn, primarily made from polyester (Polyester DTY), polyamide (nylon), or polypropylene. The magic of DTY lies not in its base material alone, but in the specific texturing process it undergoes after the initial fiber creation. This process transforms a smooth, straight POY (Partially Oriented Yarn) into a yarn with crimp, loft, and bulk.

The DTY Manufacturing Process: Adding Life to Straight Fibers

The journey of creating textured yarn like DTY involves distinct stages:

Polymer Production: Raw materials (like PTA and MEG for polyester) are polymerized into chips.

Melt Spinning: These chips are melted and extruded through spinnerets to form continuous filaments. This initial filament is POY (Partially Oriented Yarn) – thin, smooth, straight, and relatively weak.

The Crucial Texturing Stage (Draw Texturizing): This is where POY becomes DTY. The POY is fed into a texturing machine (often a false twist texturing machine). Here, three key actions happen simultaneously:

Drawing: The yarn is stretched (drawn) to align the polymer molecules, significantly increasing its tenacity (strength) and orientation.

Heating: The yarn passes through a heater, making the polymer pliable.

False Twisting & Cooling: The yarn is twisted tightly (false twist), then cooled rapidly while still twisted. When the twist is released afterwards, the filaments retain a permanent, spring-like crimp or coil.

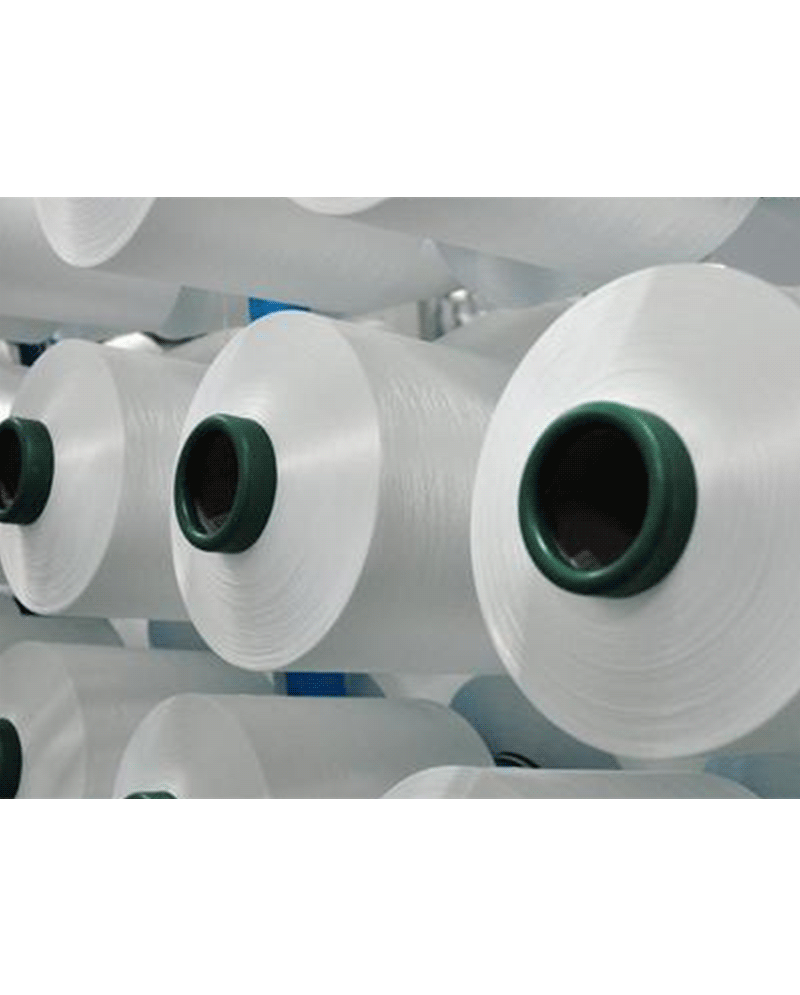

Winding: The finished DTY yarn is wound onto packages, ready for further processing like knitting or weaving.

This texturing process is what imparts the characteristic bulkiness, softness, elasticity, and opacity that distinguish DTY from its flat filament cousins like FDY (Fully Drawn Yarn).

Key Properties and Advantages of DTY Yarn

DTY yarn offers a compelling set of characteristics that drive its widespread use:

Enhanced Softness and Comfort: The crimped structure creates a much softer hand feel compared to flat filaments, making it ideal for apparel worn next to the skin.

Significant Bulk and Loft: The coiled filaments trap air, giving the yarn excellent thermal insulation properties. This bulk also contributes to better fabric coverage and opacity without excessive weight.

Improved Elasticity and Stretch: The inherent crimp allows the yarn to stretch and recover, offering garments greater comfort and freedom of movement. While not as stretchy as spandex, it provides valuable comfort stretch.

Excellent Coverage: The bulkiness means fewer yarns are often needed to cover a given area compared to finer, flat yarns, leading to potential cost efficiencies.

Good Moisture Wicking: Especially in polyester DTY, the yarn structure can effectively wick moisture away from the body, enhancing comfort during activity.

Durability and Pilling Resistance: Modern DTY, particularly high tenacity DTY, offers good strength and abrasion resistance. Air textured yarn variations can further enhance these properties. Compared to staple fiber yarns (like cotton), DTY fabrics generally exhibit superior pilling resistance.

Versatility: DTY can be produced in a wide range of deniers (thicknesses), filament counts, luster levels (bright, semi-dull, dull), and crimp levels to achieve vastly different fabric aesthetics and performance.

DTY vs. Other Common Yarn Types: A Quick Comparison

The following table highlights how DTY compares to other major yarn categories:

| Feature | DTY Yarn (Draw Textured Yarn) | FDY (Fully Drawn Yarn) | Staple Spun Yarn (e.g., Cotton) | POY (Partially Oriented Yarn) |

| Structure | Crimped/Bulk Filament | Smooth/Flat Filament | Short Fibers Twisted Together | Smooth/Flat, Undrawn/Weak |

| Hand Feel | Soft, Bulky | Smooth, Slick | Can Vary (Soft to Coarse) | Smooth, Weak |

| Bulkiness | High | Low | Moderate | Low |

| Elasticity | Moderate (Comfort Stretch) | Very Low | Low | Very Low |

| Luster | Adjustable (Dull to Bright) | Usually High | Typically Matte | Usually High |

| Strength | Good to High | High | Moderate | Low |

| Pilling | Good Resistance | Excellent Resistance | Prone to Pilling | N/A (Not used directly) |

| Primary Use | Knits, Fleece, Upholstery | Linings, Taffeta, Sari | Wovens (Shirts, Denim), Knits | Feedstock for DTY/FDY |

Widespread Applications: Where You’ll Find DTY

The unique properties of textured polyester yarn and other DTY types make them indispensable across diverse sectors:

Apparel:

Fleece Fabrics: The quintessential application. DTY’s bulk and softness create the warm, cozy fleece used in jackets, sweatshirts, and blankets.

Sportswear & Activewear: Used in tracksuits, joggers, t-shirts, and base layers due to its moisture management, comfort stretch, and durability.

Hosiery & Socks: Provides stretch, bulk, and comfort.

Lingerie & Underwear: Softness and comfort against the skin are key.

Knitwear: Sweaters, cardigans (often blended).

Home Textiles:

Upholstery Fabrics: DTY offers durability, texture, and good coverage for furniture coverings.

Bedding: Fleece blankets, quilted bedspreads, decorative fabrics.

Curtains & Drapery: Provides body and texture.

Carpets & Rugs: Used as face yarn for its resilience and texture.

Technical Textiles: Used in filtration media, geotextiles, and automotive interiors where specific strength and bulk properties are beneficial.

Choosing and Working with DTY Yarn: Key Considerations

When sourcing or specifying textured filament yarn like DTY, consider these factors:

Denier and Filament Count: Thicker deniers offer more bulk and durability, finer deniers give a softer drape. Filament count affects hand feel and texture.

Crimp Level: Higher crimp equals more bulk and stretch but can sometimes impact processing efficiency.

Luster: Bright, semi-dull, or dull options impact the final fabric’s appearance.

Tenacity: For demanding applications, high tenacity DTY is crucial. Consider yarn elongation properties too.

Shrinkage: Be aware of potential thermal shrinkage during dyeing or finishing. Low shrinkage DTY is available for critical applications.

Dyeability: Ensure the DTY grade is suitable for the intended dyeing process (disperse dyes for polyester).

Conclusion: The Enduring Value of Texture

DTY yarn, born from the ingenious texturing process applied to synthetic filaments, remains a cornerstone of the modern textile industry. Its ability to deliver unparalleled softness, comforting bulk, valuable stretch, and reliable performance makes it far more than just a commodity fiber. From the warmth of your favorite fleece jacket to the durability of your sofa fabric, DTY yarn properties like bulkiness and improved elasticity contribute significantly to the functionality and feel of countless everyday products. Understanding its characteristics and production process empowers better material selection, leading to textiles that truly meet their intended purpose, combining comfort, durability, and value. As textile technologies evolve, DTY continues to adapt, solidifying its role as an essential synthetic filament yarn for diverse applications.

English

English 中文简体

中文简体