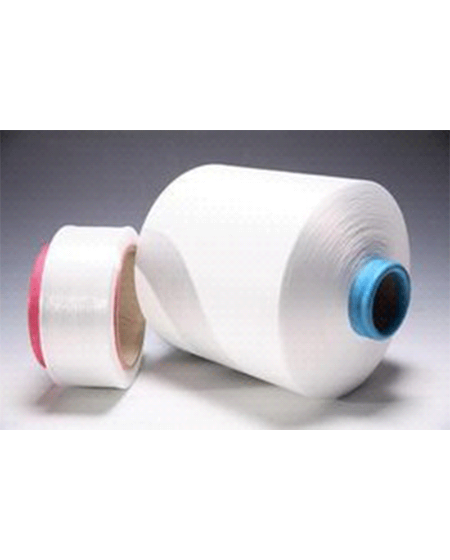

Full Draw, Partially Oriented and Textured Polyester Yarn

Author: admin / 2023-03-17

Fully Draw Yarn (FDY) is a multi-filament yarn that is stretched to its full length during the spinning process of polyester chip or flake. It is then orientated to meet the tenacity, shrinkage and elongation properties desired in a particular application.

Partially Oriented Yarn (POY)

The melting and extrusion of polyethylene terephthalate (PTA) chips or flake into a continuous filament yarn is achieved by melt-spinning the polymer at take-off speeds of 550 to 1640 yards per minute (500 to 1500 meters/minute). As-spun POY yarn is drawn at a draw ratio of about 3.5 to 4.5 times its greater length, which produces the uniform, fully drawn POY yarn of commerce.

Textured Polyester Yarn

In addition to its tenacity, elongation, Uster variation and boiling water shrinkage, the polymer has excellent elasticity, crimp and dye uptake characteristics when properly spun and textured. These characteristics make textured POY suitable for texturizing, and a number of other textile processing applications.

Drawn textured polyester yarns have thick and thin sections of cross-sectional areas which are randomly distributed along the filament length of the yarn. They are typically deeper-dyed than the corresponding sections in fully drawn POY.

The incompletely drawn spin-oriented yarn is preferably false-twist textured by conventional processes used for fully drawn polyester yarn, with heater temperatures greater than 200deg C., to produce textured yarn that has good bulk and no melting of the thick sections. The incompletely drawn spin-oriented yarn can also be woven or knitted using a single machine that is modified to complete the drawing process prior to the texturing heater, or a tandem draw-texturing process in which the incompletely drawn spin-oriented yarn is incompletely drawn in a draw zone and then false-twist textured in a false-twist texturing zone.

English

English 中文简体

中文简体