Can Recycled POY Yarn Be Used in High-Performance Fabrics?

The global textile industry is undergoing a profound transformation. As sustainability rises from a niche concern to a mainstream priority, manufacturers, designers, and consumers alike are re-examining the raw materials that make up the fabrics of daily life. Among the innovations gaining traction is recycled POY yarn, a material derived from post-consumer and post-industrial polyester waste that is re-spun into usable fiber. While it already finds applications in everyday textiles, a critical question lingers: Can recycled POY yarn truly be used in high-performance fabrics?

Exploring this question requires a closer look at what recycled POY yarn is, how it is made, its technical properties, and whether it can match the demanding standards of performance-based fabrics.

Understanding POY Yarn and Its Recycled Counterpart

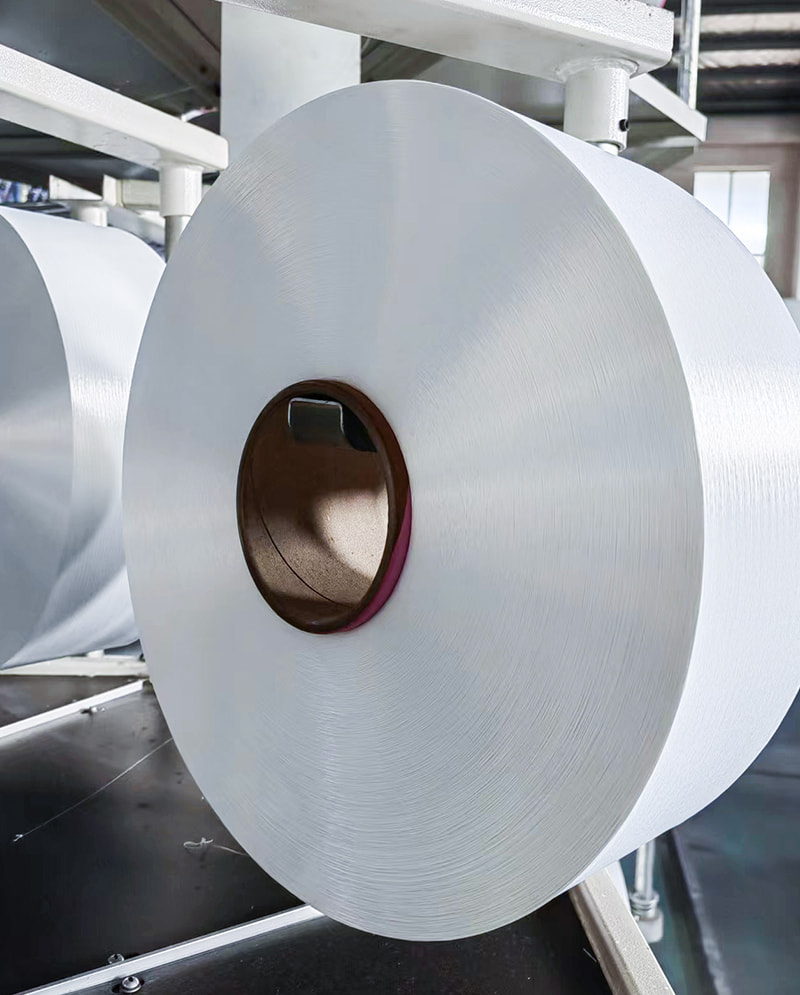

POY (Partially Oriented Yarn) refers to a type of polyester filament yarn produced during the early stages of the fiber-making process. It is partially stretched, leaving it in an intermediate state that can be further drawn, textured, or processed depending on the intended end use. POY is a foundational yarn, often transformed into DTY (Draw Textured Yarn) or other variations to suit apparel, upholstery, or industrial textiles.

Recycled POY yarn is produced through similar processes but begins with recycled polyester feedstock instead of virgin petrochemical-based raw materials. This feedstock often comes from PET bottles, textile waste, or other polyester scraps. Through advanced recycling and re-polymerization, the material is converted back into polymer chips, melted, extruded, and spun into yarn.

The result is a product that mirrors conventional POY in structure, but with a significantly reduced environmental footprint.

Why High-Performance Fabrics Demand More

High-performance fabrics are not defined by style alone; they are engineered for functionality under stress. Common applications include:

- Sportswear and activewear requiring stretch, breathability, and sweat-wicking.

- Outdoor gear needing durability, UV resistance, and water repellency.

- Industrial textiles demanding abrasion resistance, dimensional stability, and load-bearing strength.

- Medical and technical fabrics where hygiene, sterility, and resilience are critical.

Such applications require yarns with consistent tensile strength, uniformity, and reliable dyeing characteristics. Even minor deviations in yarn quality can affect the performance of the final fabric. This raises the question: can recycled POY yarn meet these stringent demands?

Technical Properties of Recycled POY Yarn

1. Strength and Durability

Recycled POY yarn, when processed with controlled polymerization and extrusion techniques, can achieve comparable tensile strength to virgin polyester POY. Research and industry trials suggest that the mechanical performance differences are often minimal when modern recycling technology is used.

2. Moisture and Chemical Resistance

Like virgin polyester, recycled POY yarn retains its hydrophobic properties, resisting moisture absorption. It is also resistant to most chemicals, making it suitable for environments where exposure to sweat, cleaning agents, or environmental pollutants is common.

3. Thermal Behavior

Polyester’s thermal properties remain stable in recycled form, allowing fabrics made from recycled POY to withstand heat-setting, dyeing, and finishing processes without significant compromise.

4. Spinnability and Texturing

Recycled POY yarn can be drawn and textured into DTY or other forms, making it versatile for different textile applications. This adaptability ensures that it can enter production lines intended for virgin POY with minimal modification.

Advantages of Using Recycled POY Yarn in High-Performance Fabrics

1. Sustainability and Waste Reduction

High-performance textiles, particularly in the sportswear and outdoor industries, have faced scrutiny for their environmental impact. Using recycled POY yarn significantly reduces reliance on virgin petroleum resources and diverts plastic waste from landfills and oceans.

2. Comparable Functional Performance

Advances in recycling technology have narrowed the performance gap between virgin and recycled polyester. In many applications, recycled POY yarn demonstrates equal performance, making it a viable choice for demanding fabric needs.

3. Compatibility with Modern Fabric Innovations

Recycled POY yarn integrates well with blends and composites. For instance, it can be combined with elastane to produce stretch fabrics or with natural fibers for hybrid functionality.

4. Consumer Appeal

End-users increasingly value products that balance performance with responsibility. High-performance fabrics made with recycled content meet a dual demand: technical reliability and eco-consciousness.

Challenges and Limitations

While recycled POY yarn offers promising attributes, some challenges must be acknowledged.

-

Quality Variability

Recycled feedstock can introduce inconsistencies if not carefully sorted, cleaned, and processed. Impurities in the recycled stream may affect polymer chain length, leading to variations in yarn quality. -

Higher Processing Demands

Maintaining uniform molecular weight and viscosity in recycled polyester requires advanced recycling technologies. Without these, yarn may exhibit reduced strength or uneven dye uptake. -

Performance Boundaries

In applications requiring extreme mechanical strength—such as heavy-duty industrial fabrics—virgin polyester may still hold an edge in consistency and durability. -

Cost Considerations

Although recycling reduces environmental costs, the economic cost can sometimes be higher due to additional sorting and processing. This may influence the adoption rate, especially in cost-sensitive markets.

Industry Adoption and Case Studies

The shift toward recycled POY yarn is not theoretical—it is actively unfolding across textile sectors. Sportswear companies increasingly experiment with recycled polyester blends in performance apparel. Outdoor brands also integrate recycled yarns into jackets, backpacks, and gear coverings, citing both performance reliability and sustainability.

Additionally, industrial textile manufacturers have tested recycled POY yarn in applications such as seat belts, safety harnesses, and geotextiles. While not all uses have transitioned fully, early results indicate that many performance requirements can be met or closely approximated by recycled alternatives.

The Role of Innovation in Expanding Capabilities

Future progress lies in continued technological refinement. Chemical recycling, for example, offers greater control over polymer chain length than mechanical recycling, producing recycled polyester with near-virgin properties. As these methods become more scalable, recycled POY yarn will become increasingly indistinguishable from virgin POY in performance metrics.

Furthermore, blending recycled yarn with biodegradable coatings, nanotechnology, or smart textiles could expand its functionality in high-performance fabrics, ranging from moisture regulation to energy storage.

Practical Considerations for Manufacturers

For textile producers considering recycled POY yarn in high-performance fabrics, the following steps are crucial:

- Source Reliable Suppliers: Ensuring consistency in raw materials is essential for maintaining yarn quality.

- Test Performance Rigorously: Conduct tensile strength, dyeing, and durability tests to verify performance requirements.

- Blend Strategically: Combining recycled POY with other fibers may optimize both sustainability and function.

- Highlight Sustainability in Marketing: While the focus should remain on performance, communicating recycled content resonates with modern consumers.

Looking Ahead

So, can recycled POY yarn be used in high-performance fabrics? The answer is increasingly yes—with qualifications. While challenges remain in ensuring absolute consistency and performance for the most demanding applications, technological advancements and industry trials show that recycled POY yarn can stand shoulder-to-shoulder with its virgin counterpart in many contexts.

As innovation continues, the line between “recycled” and “high-performance” is blurring. Rather than being seen as a compromise, recycled POY yarn is emerging as a practical, sustainable, and reliable choice for forward-thinking textile manufacturers.

Conclusion

The future of textiles lies in reconciling performance with sustainability. High-performance fabrics cannot afford to sacrifice functionality, but they also cannot ignore the environmental urgency pressing upon the industry. Recycled POY yarn offers a promising bridge between these two imperatives. With careful sourcing, technological refinement, and strategic application, it has the potential to not only meet performance standards but also redefine them.

English

English 中文简体

中文简体